Yes, we need to go the FAB way as a people. By the way, what is FAB? FAB is an abbreviation of the word FABRICATION, which is frequently used in the manufacturing space, especially in chips. Again, what are chips? Chips are processed silicon materials that electronics devices run on. Our world today is driven by electronics - from our cars to televisions, smartphones, microwaves, and the list goes on.

Chips are the brain that power these devices. Last year (2021), there was a global shortfall of chips . Powerhouses in the manufacturing of semiconductors like Taiwan Semiconductor Manufacturing Company Limited (TSMC) and Semiconductor Manufacturing International Corporation (SMIC) could not meet the demands of customers. This shortfall was caused by huge demands for these products during the lockdown.

A Chip Wafer (credit. techsciresearch.com)

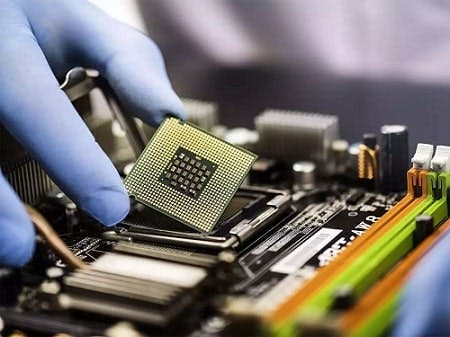

The China-USA trade war fracas, amongst other things, has also caused a lot of commitment by semiconductor giants such as Samsung and Intel to invest billions of dollars in new chip manufacturing plants across Europe and the U.S.

In the meantime, the chip shortage has hampered the ability of car manufacturers to push out new cars, and companies like Arduino have been unable to produce new lines of existing and new products. In all these, what does this means for us as Nigerians? It means a multi-billion-dollar sector to tap in. The question remains, can we tap into a sector where we practically do not have a lot of expertise?

There are big players in this space. The likes of Intel and Samsung have years of research and manufacturing under their belts. China and India have models of companies coming from the back seat to take the place of importance in the world of technology. China turned a fishing village into the world's hardware capital in just about 40 years. Currently, the number of people involved in this space is relatively low compared to the software space.

There are big players in this space. The likes of Intel and Samsung have years of research and manufacturing under their belts. China and India have models of companies coming from the back seat to take the place of importance in the world of technology. China turned a fishing village into the world's hardware capital in just about 40 years. Currently, the number of people involved in this space is relatively low compared to the software space.

Nigerians can get into this space by getting involved in the hardware ecosystem. One major step is revamping our education system from primary to tertiary levels of education. Our curriculum must be practical-based rather than the archaic theoretical system we currently operate. Children can start learning with the available electronics kits such as micro bits and Arduino.

Furthermore, we also need to strengthen our people's 'tooling' culture. Taking a cue from China, people who deal with tooling has taken the skill and made it an art that has become part and parcel of them rather than something they do for a living. We already have an apprenticeship culture among the Igbo people, which can be built upon and leveraged.

Josef Prusa, 3D Printing Farm, An example of a FabLab (Credits: Prusa Research)

Josef Prusa, 3D Printing Farm, An example of a FabLab (Credits: Prusa Research)

The government, usually called the big spender, also needs to be involved. It is time to design and initiate friendly policies and can attract the big guys to come and invest in infrastructure, training and development. It is also of great priority that foreign companies that are invited to manufacture in Nigeria use local content agreement both in raw material and human resource, this will enable smooth technology transfer which will make us independent on the long run.

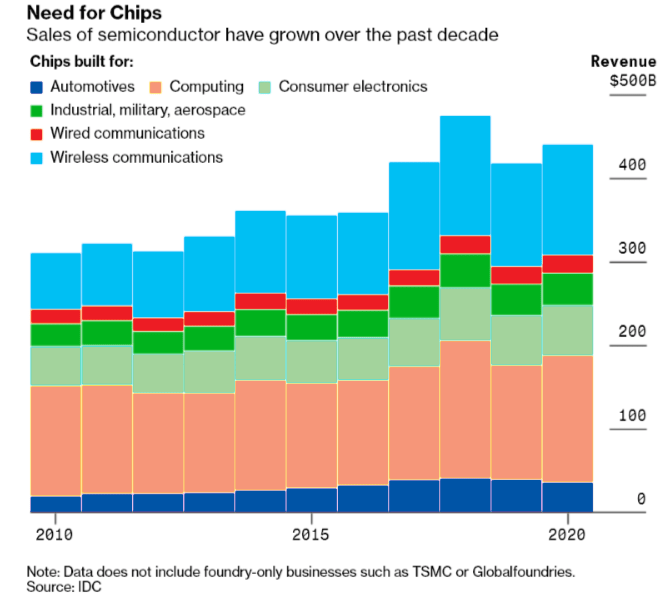

It is time we have a government that can be strategic and speak to manufacturers on the need to invest. ARM recently opened a center for training and research in South Africa, and Microsoft also launched its Africa Development Center in Nigeria and Kenya. We have a population with a young mean age and stand a chance to benefit a lot from this multi-billion economy. As projected, the use of electronics will grow year on year. We have been consumers over the years. It is time to become active manufacturers in this space.